Join the VentureBeat Community

Free: Join the VentureBeat Community for access to 3 premium posts or videos a month.

Learn MoreBy continuing, you are indicating that you accept our Terms of Service and Privacy Policy.

Research Library

The top resource for free research, white papers, reports, case studies, magazines, and eBooks.

- Information Technology

- Data Infrastructure

- Data Tools

- Desktops, Laptops and OS

- Chip Sets

- Collaboration Tools

- Desktop Systems - PCs

- Email Client

- Embedded Systems

- Hardware and Periferals

- Laptops

- Linux - Open Source

- Mac OS

- Memory Components

- Mobile Devices

- Presentation Software

- Processors

- Spreadsheets

- Thin Clients

- Upgrades and Migration

- Windows 7

- Windows Vista

- Windows XP

- Word Processing

- Workstations

- Enterprise Applications

- IT Infrastructure

- IT Management

- Networking and Communications

- Bluetooth

- DSL

- GPS

- GSM

- Industry Standard Protocols

- LAN - WAN

- Management

- Mobile - Wireless Communications

- Network

- Network Administration

- Network Design

- Network Disaster Recovery

- Network Interface Cards

- Network Operating Systems

- PBX

- RFID

- Scalability

- TCP - IP

- Telecom Hardware

- Telecom Regulation

- Telecom Services

- Telephony Architecture

- Unified Communications

- VPNs

- VoIP - IP Telephony

- Voice Mail

- WAP

- Wi-Fi (802.11)

- WiMAX (802.16)

- Wide Area Networks (WAN)

- Wireless Internet

- Wireless LAN

- Security

- Servers and Server OS

- Software and Web Development

- .Net Framework

- ASPs

- Application Development

- Application Servers

- Collaboration

- Component-Based

- Content Management

- E-Commerce - E-Business

- Enterprise Applications

- HTML

- IM

- IP Technologies

- Integration

- Internet

- Intranet

- J2EE

- Java

- Middleware

- Open Source

- Programming Languages

- Quality Assurance

- SAAS

- Service-Oriented Architecture (SOA)

- Software Engineering

- Software and Development

- Web Design

- Web Design and Development

- Web Development and Technology

- XML

- Storage

- Agriculture

- Automotive

- Career

- Construction

- Education

- Engineering

- Finance

- Food and Beverage

- Government

- Healthcare and Medical

- Human Resources

- Information Technology

- Data Infrastructure

- Data Tools

- Desktops, Laptops and OS

- Chip Sets

- Collaboration Tools

- Desktop Systems - PCs

- Email Client

- Embedded Systems

- Hardware and Periferals

- Laptops

- Linux - Open Source

- Mac OS

- Memory Components

- Mobile Devices

- Presentation Software

- Processors

- Spreadsheets

- Thin Clients

- Upgrades and Migration

- Windows 7

- Windows Vista

- Windows XP

- Word Processing

- Workstations

- Enterprise Applications

- IT Infrastructure

- IT Management

- Networking and Communications

- Bluetooth

- DSL

- GPS

- GSM

- Industry Standard Protocols

- LAN - WAN

- Management

- Mobile - Wireless Communications

- Network

- Network Administration

- Network Design

- Network Disaster Recovery

- Network Interface Cards

- Network Operating Systems

- PBX

- RFID

- Scalability

- TCP - IP

- Telecom Hardware

- Telecom Regulation

- Telecom Services

- Telephony Architecture

- Unified Communications

- VPNs

- VoIP - IP Telephony

- Voice Mail

- WAP

- Wi-Fi (802.11)

- WiMAX (802.16)

- Wide Area Networks (WAN)

- Wireless Internet

- Wireless LAN

- Security

- Servers and Server OS

- Software and Web Development

- .Net Framework

- ASPs

- Application Development

- Application Servers

- Collaboration

- Component-Based

- Content Management

- E-Commerce - E-Business

- Enterprise Applications

- HTML

- IM

- IP Technologies

- Integration

- Internet

- Intranet

- J2EE

- Java

- Middleware

- Open Source

- Programming Languages

- Quality Assurance

- SAAS

- Service-Oriented Architecture (SOA)

- Software Engineering

- Software and Development

- Web Design

- Web Design and Development

- Web Development and Technology

- XML

- Storage

- Life Sciences

- Management

- Manufacturing

- Marketing

- Meetings and Travel

- Multimedia

- Operations

- Retail

- Sales

- Trade/Professional Services

- Utility and Energy

- View All Topics

- Featured eBooks

- Trending Resources

- New Resources

- Promote Your Content

- Partnership Opportunities

- Get RSS Updates

- About TradePub.com

- FAQ

- Contact Us

Share Your Content with Us

on TradePub.com for readers like you. LEARN MORE

Request Your Free White Paper Now:

"Key Reasons and Advantages for Conducting Press Hydraulic Retrofits"

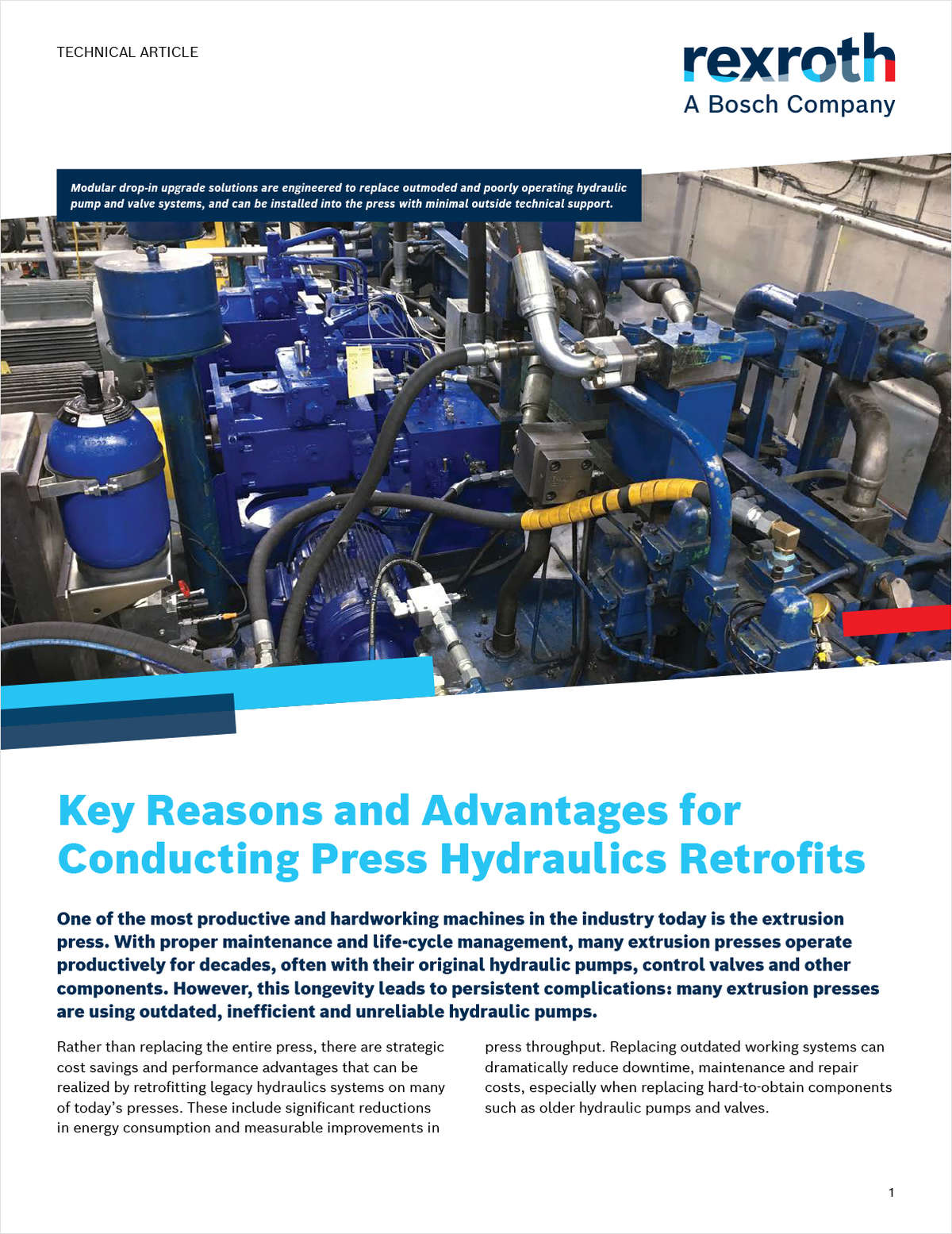

Download the new technical article to learn how upgrading legacy extrusion press hydraulic systems can dramatically improve press performance, reduce costs and extend its operational life.

With proper maintenance and life-cycle management, many extrusion presses operate productively for decades. Eventually, however, hydraulic pumps, control valves and other devices can no longer be maintained and repaired, leading to increased press downtimes and inefficient operation.

This technical article details the costs and impact of operating extrusion presses with out-of-date hydraulics. It also provides an approach to solving these challenges: retrofitting legacy hydraulics systems with a modular hydraulics replacement solution.

Today’s high-performance hydraulics technology incorporates smart technologies and connectivity that make it easier to implement Industry 4.0 capabilities such as advanced diagnostics, predictive maintenance and real-time production data collection. The article describes how these technologies offer:

- Improved speed, force and torque control with the latest “smart” servo-hydraulics

- Significantly improved hydraulic pump life cycles — up to 60,000 hours in extrusion presses

- Much less press downtime, leading to improved throughput and ROI

- Improved energy efficiency and reduced costs of maintenance and fluid leak cleanups

- Simplified modular hydraulics retrofit process: new hydraulics can often be installed in one or two days

Offered Free by: Bosch-Rexroth

See All Resources from: Bosch-Rexroth